| Material: | Kevlar Sewing Thread | |

| Yarn Count: | 20’S/2~20’S/6, 30’S/2~30’S/6, 40’S/2~40’S/3 | 200D/2,200D/3,400D2 |

| Type: | Spun | Filament |

| Length/spool: | 2500~5500 meters | 1500~3000 meters |

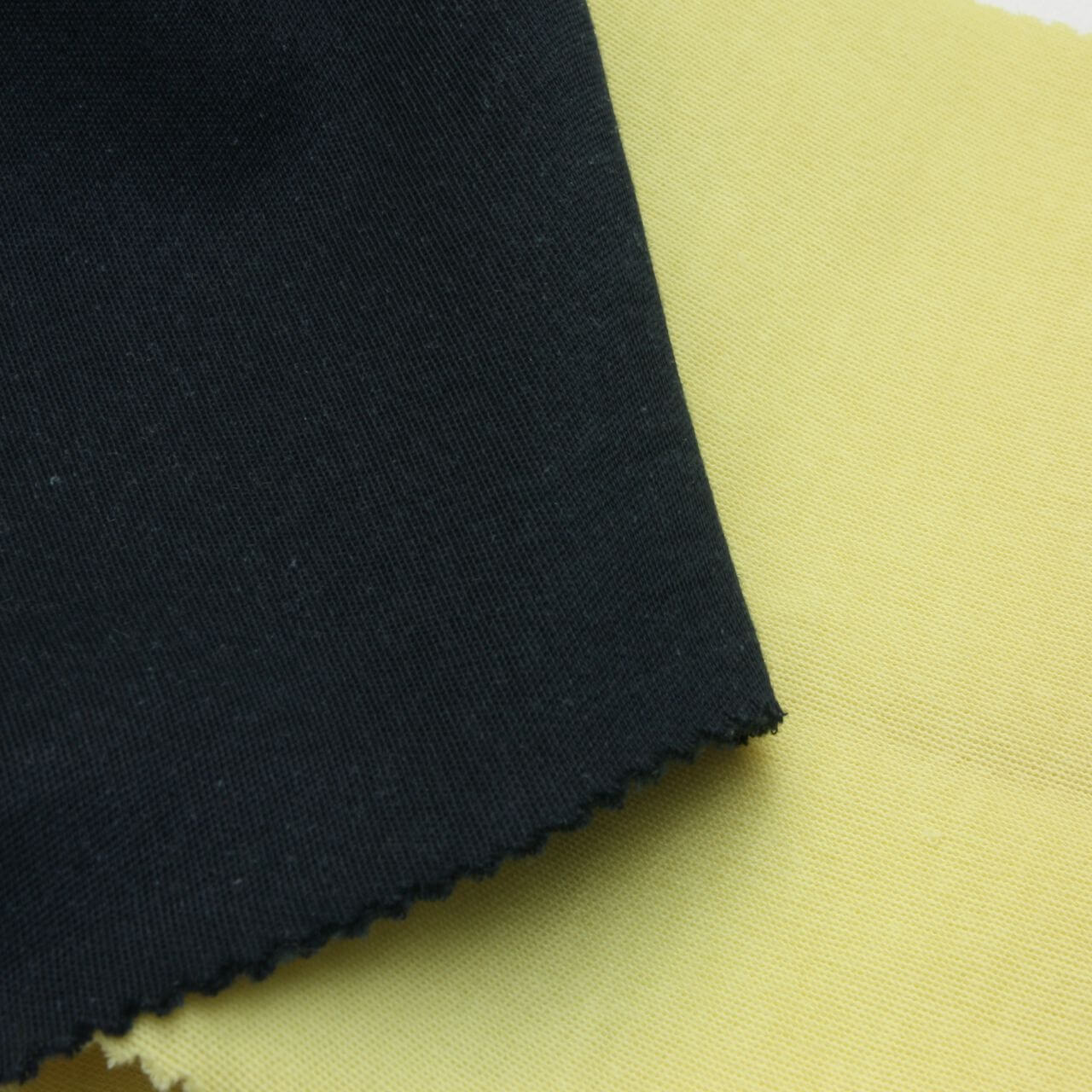

| Color: | Natural Yellow/Black | Natural Yellow |

| Feature: | High strength, durability, high tear resistance | |

| Fire resistant, no melt/drip, self-extinguishing after contact a flame | ||

| Good chemical resistance against weak acids and alkalis | ||

| Limiting oxygen index Loi greater than 28 | ||

| Excellent mechanical strength | ||

Tips Of Saving Kevlar Sewing Thread

Will pack all our Kevlar sewing thread in black polythene bags to ensure that they are in pristine condition when received. Because all Kevlar products are affected by strong UV light and will reduce the strength if left exposed to sunlight or UV for long periods. Kevlar will also degrade in contact with chlorine (such as bleach).

Learn more about fire retardant thread and Nomex thread.