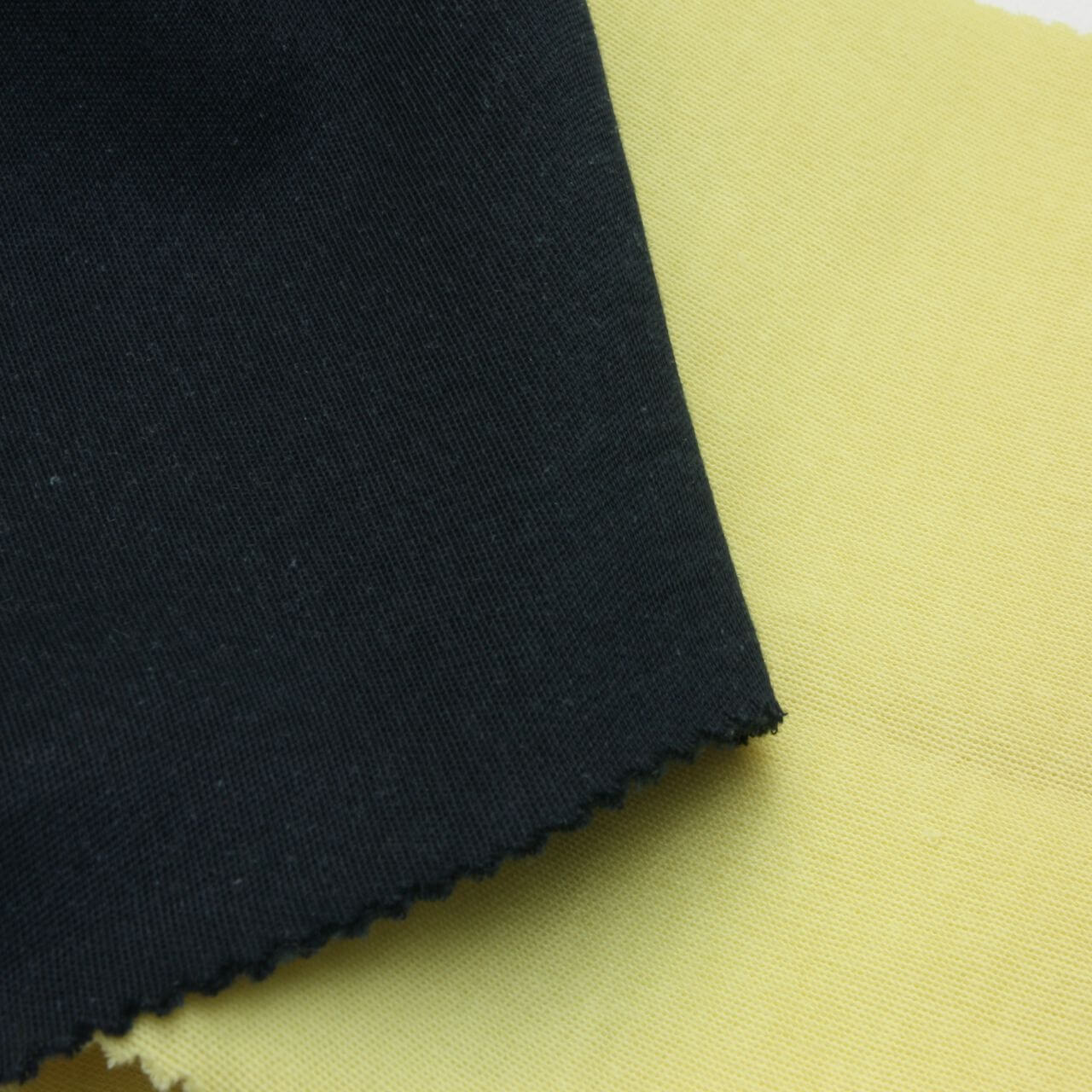

Kevlar® Abrasion Resistant Fabric

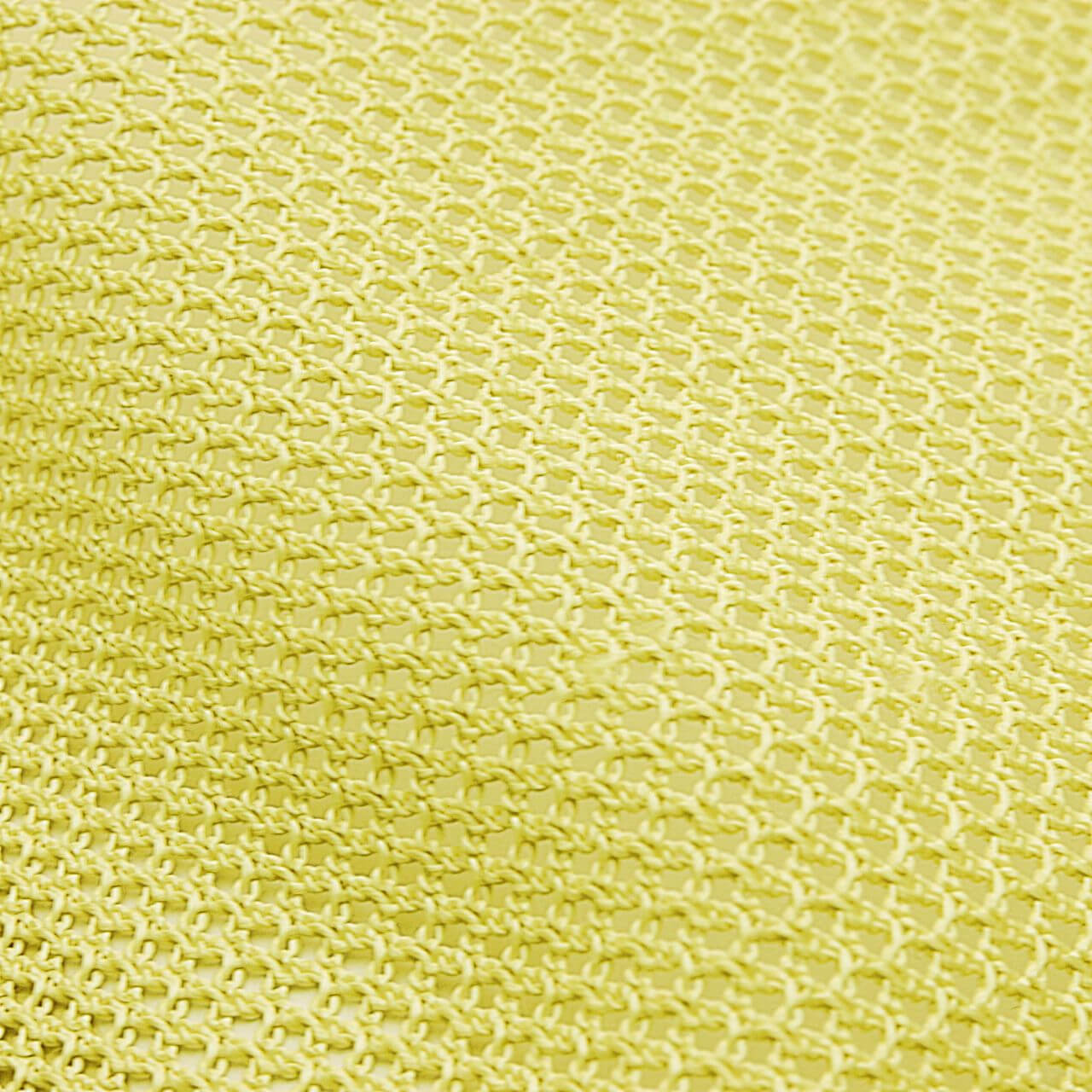

Characteristics Of Kevlar® Fabric: Abrasion Resistant

Abrasion resistance is the ability of Kevlar fabric to resist surface wear caused by flat rubbing contact with another material. Kevlar fabric, known for its exceptional abrasion resistance, can withstand surface wear from rubbing, thereby extending the life of a product and providing protection to the wearer.

Uses And Applications of Abrasion Resistant Fabrics

Abrasion resistant fabrics are specially designed materials with the capacity to resist injuries, erosion, scratches, extreme weather, and more. These textiles find applications in a wide range of fields, including defense, civil defense, firefighting, marine, automotive, glass manufacturing, electrical, mechanical, engineering, and many others.

The versatility and protective capabilities of abrasion resistant fabrics make them essential in numerous industries, ensuring enhanced safety, longevity, and performance in challenging environments.

Advantage of Our Kevlar® Fabric

Our Kevlar® fabric offers exceptional abrasion resistance, making it a superior choice among common abrasion-resistant materials. Made with DuPont™ Kevlar® para-aramid fiber, it is lightweight, durable, and incredibly strong. Our fabric finds extensive use in various applications such as cut-resistant garments, abrasion-resistant clothing, flame retardant accessories, motor jeans liners, and stab-resistant body armor. Choose our Kevlar® fabric for superior performance and reliable protection in demanding environments.

(You may also like: Flame Resistant Fabric & FR Knitting Fabric & Fire Retardant Thread – Nomex/Kevlar Sewing Thread)

Showing all 2 results